Long service life, durable, and maintains high performance over extended usage periods.High load capacity allows for handling heavier loads.

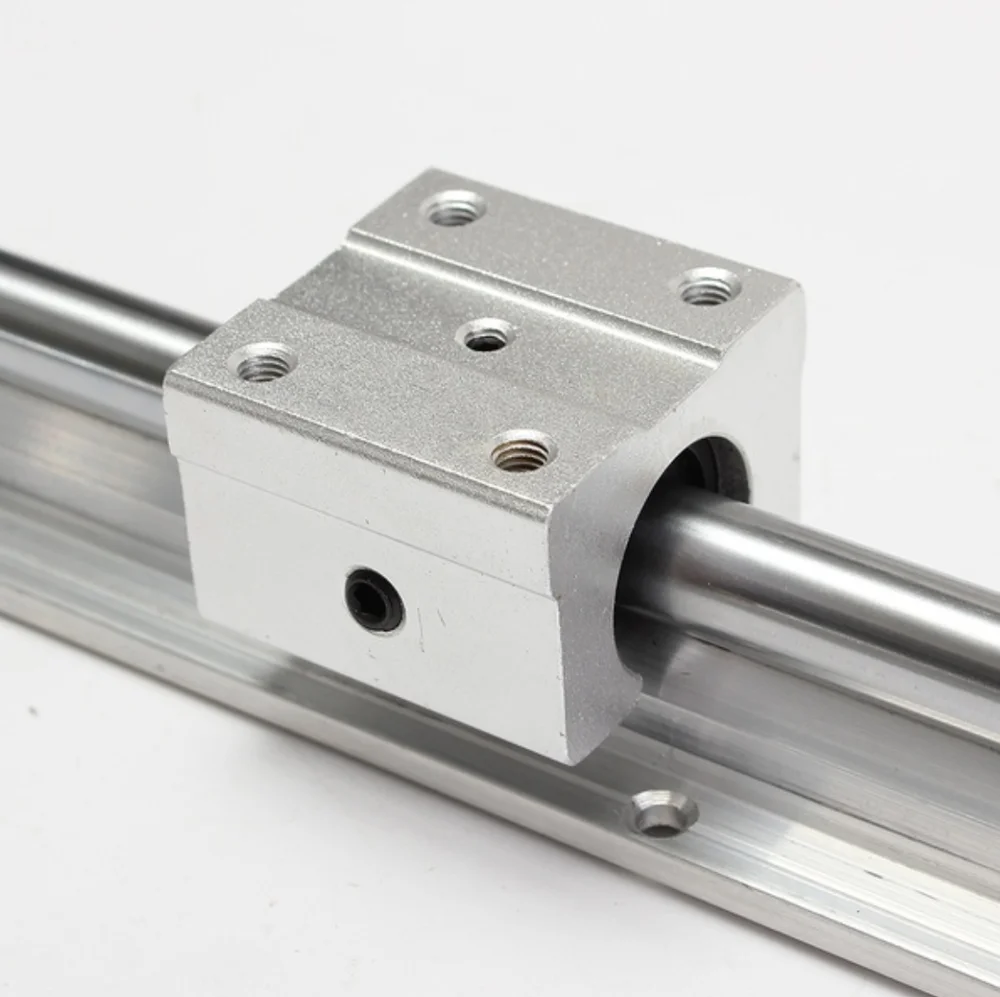

As Figure: Linear Guide Rail Applications From the friction, can withstand the load consideration, square guide is the guide and slider surface contact friction, friction is larger, uniform load, need frequent oil lubrication. As shown:īy the square slider and square guide with the use of square, from the appearance of square. The installation and use of circular guide are more convenient, saving space. At the same time, linear bearings can also be used with the slider to achieve flat installation.

Types of Linear Guide Railīy the linear bearing and linear shaft with the use, from the appearance of the cylindrical, can be assembled with a circular hole. The carriage has four rows of steel balls (two rows for miniature rails) that facilitate smooth motion by rolling along the rail. Components of a Linear RailĪ linear guide rail is mainly composed of a rail and a carriage. One of its key benefits is its capability to deliver reliable motion within a limited space. It is utilized in various industries, including machine tools, electronics, medical devices, and robotics. A linear rail enables accurate linear motion with exceptional precision in high-load scenarios. It can handle torque to a certain extent.

#Cnc linear rail manual#

That can be programmed in a variety of modes, including: single position, manual operation and position calculation for bar processing applications. The automatic unit is computer controlled by a single axis Type 550 Control, with a digital display and 24 button keypad. The material is guided in place by a set of guiding rollers. It is ideally suited to do repetitive and ‘one off’ work without the need for marking out, increasing production speeds and eliminating costly operator error. “I” is available with a standard length of 4.00m (giving an operating distance of 3.60m) extendable in 1.00m lengths to suit the user’s application. The CNC Linear Rails allow cost effective punching and notching of flat bar, angles, channels, ‘T’ and ‘I’ beams. Both solutions are capable to be adapted for any linear feeding of bars, tubes and profiles. The more sophisticated CNC controlled Linear Rail feeder is the ideal device for structural steel and engineering workshops. The KS manual linear feeder with tilting stops (2, 4 or 6m long) is a versatile, flexible and budget friendly linear feeder solution. Automatic Linear Feeder for Press 4M from Capital Machinery Sales on Vimeo.

0 kommentar(er)

0 kommentar(er)